The Loop QC app is essential for quality control, facilitating inspections, data collection, and observation recording, ensuring compliance with concrete quality standards.

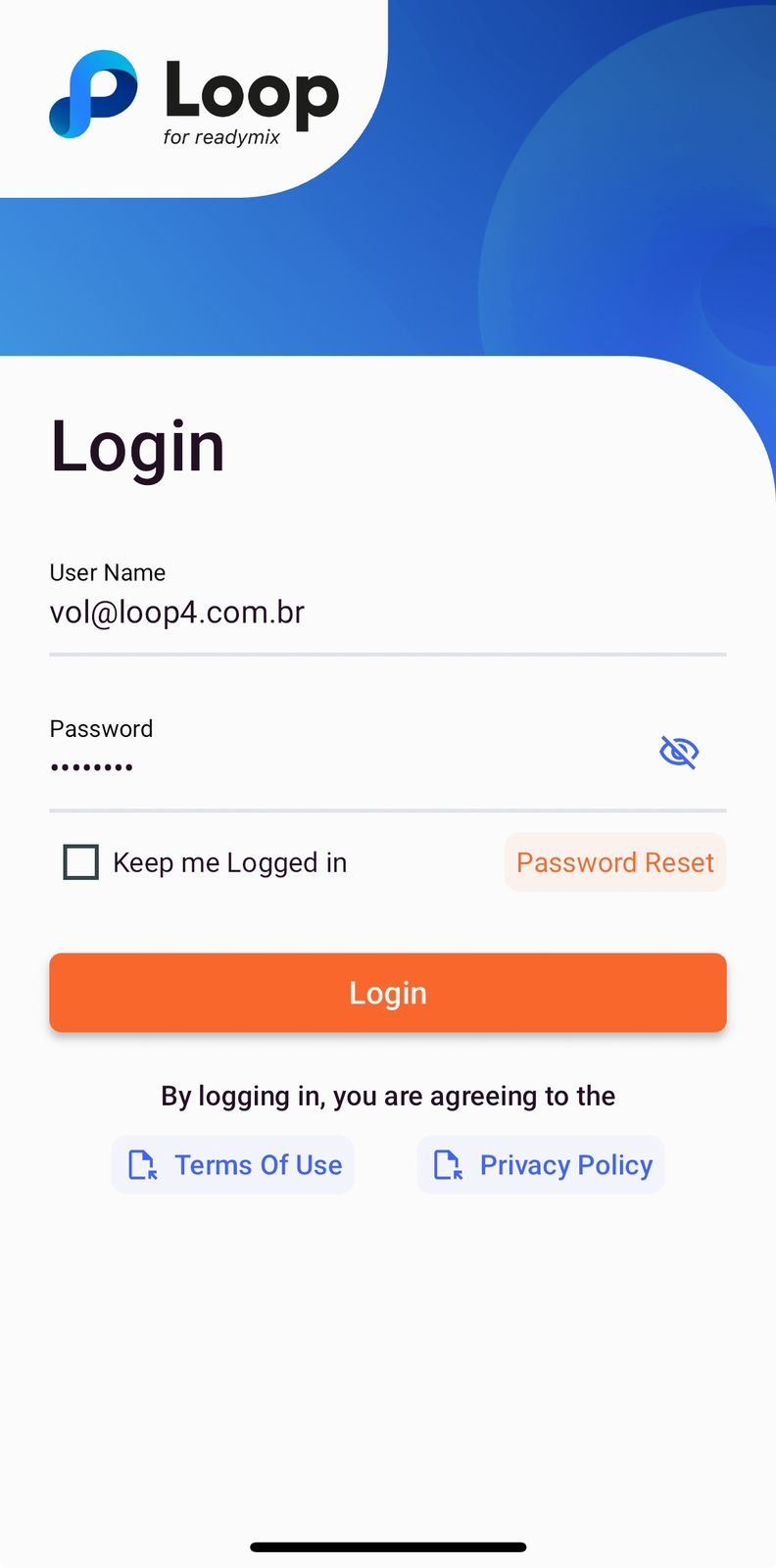

Login

To access the application, log in using the same "User Name" and "Password" as the Loop system. This login ensures that each inspection is linked to the correct user.

You can stay logged in (by checking the "Keep me Logged in" option) and also reset the password (by clicking the "Password Reset" option).

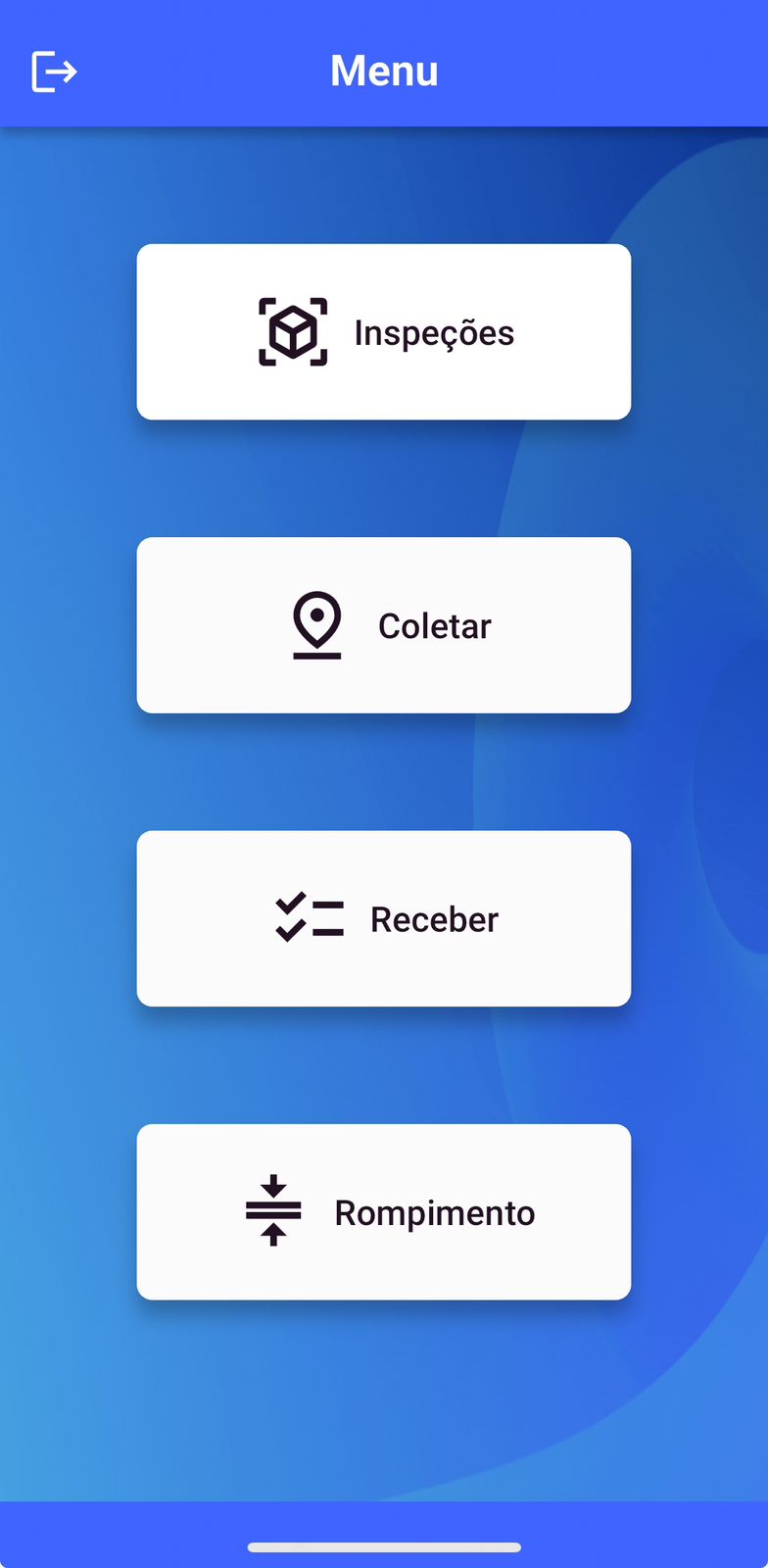

Menu

After logging in, you will be directed to the Menu screen. This section lists all the steps, including: Inspections, Collect, Receive, and Break Up.

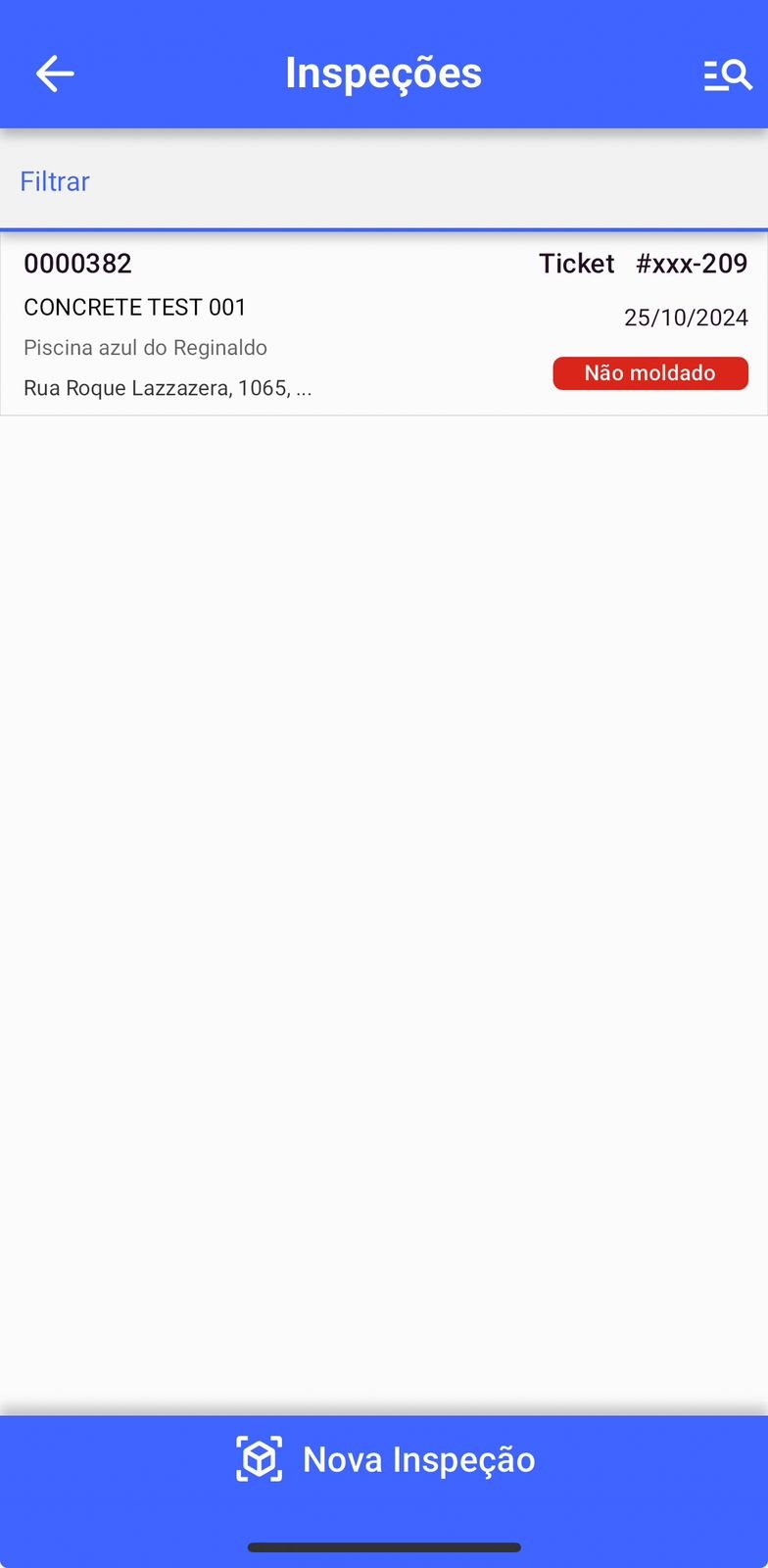

Inspections

This section lists all scheduled inspections, which can be filtered. Each inspection includes important information such as location, ticket number, status, date, inspection name, and sample code.

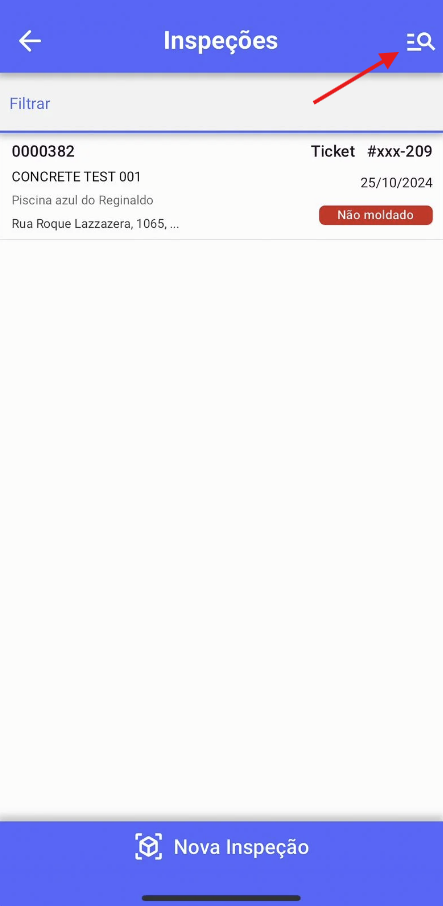

Filtering Inspections

Using the filter, you can locate inspections for a specific period as needed.

Editing Existing Inspections

By selecting an inspection, you can:

Enter information, add the sample mold number, and scan its QR Code.

Creating a New Inspection

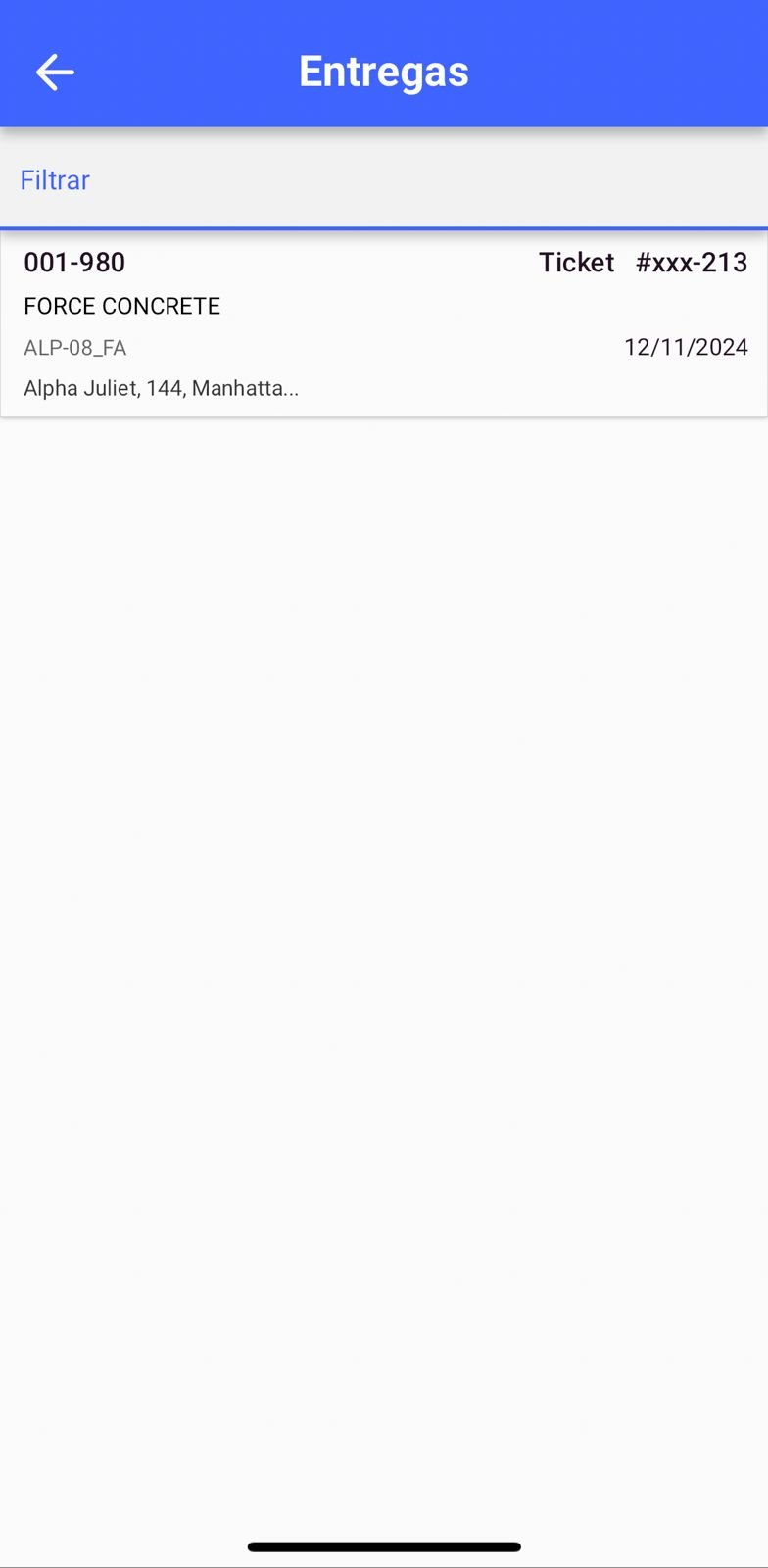

Additionally, you can perform a new inspection by clicking the "New Inspection" button. By clicking, you will be directed to the Deliveries screen, where all deliveries will be listed.

By selecting a delivery, you will have information such as plant name, ticket code, date, volume, product name, address, and delivery code. You can also select the laboratory and inspection type.

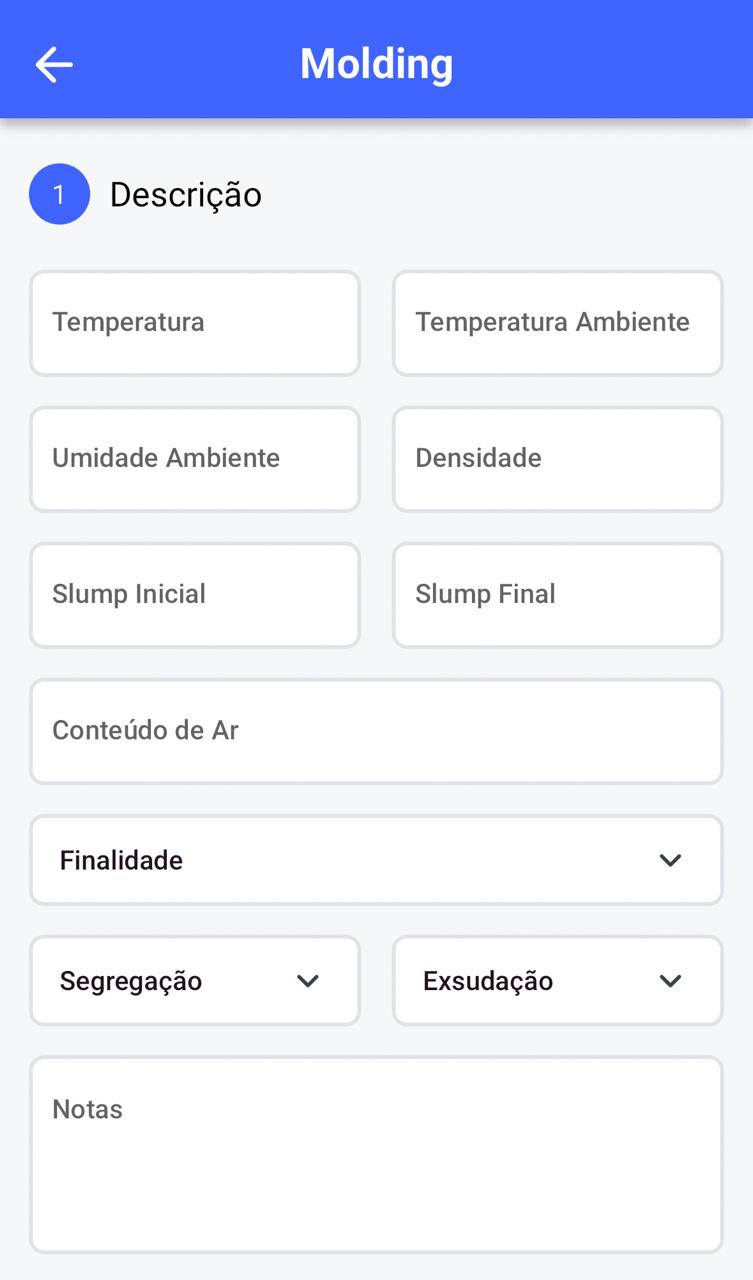

After saving, a new screen will open where you can enter detailed inspection information, including:

Temperature

Ambient Temperature

Ambient Humidity

Density

Initial Slump

Final Slump

Air Content

Purpose

Segregation

Bleeding

Document with the Notes field

Add sample images as needed

Collect

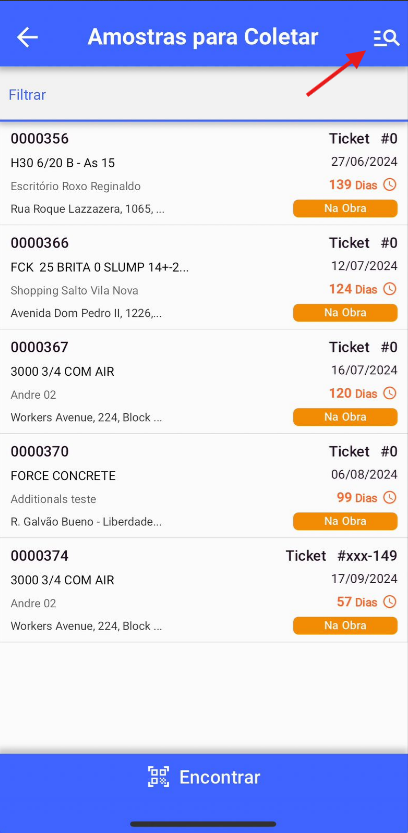

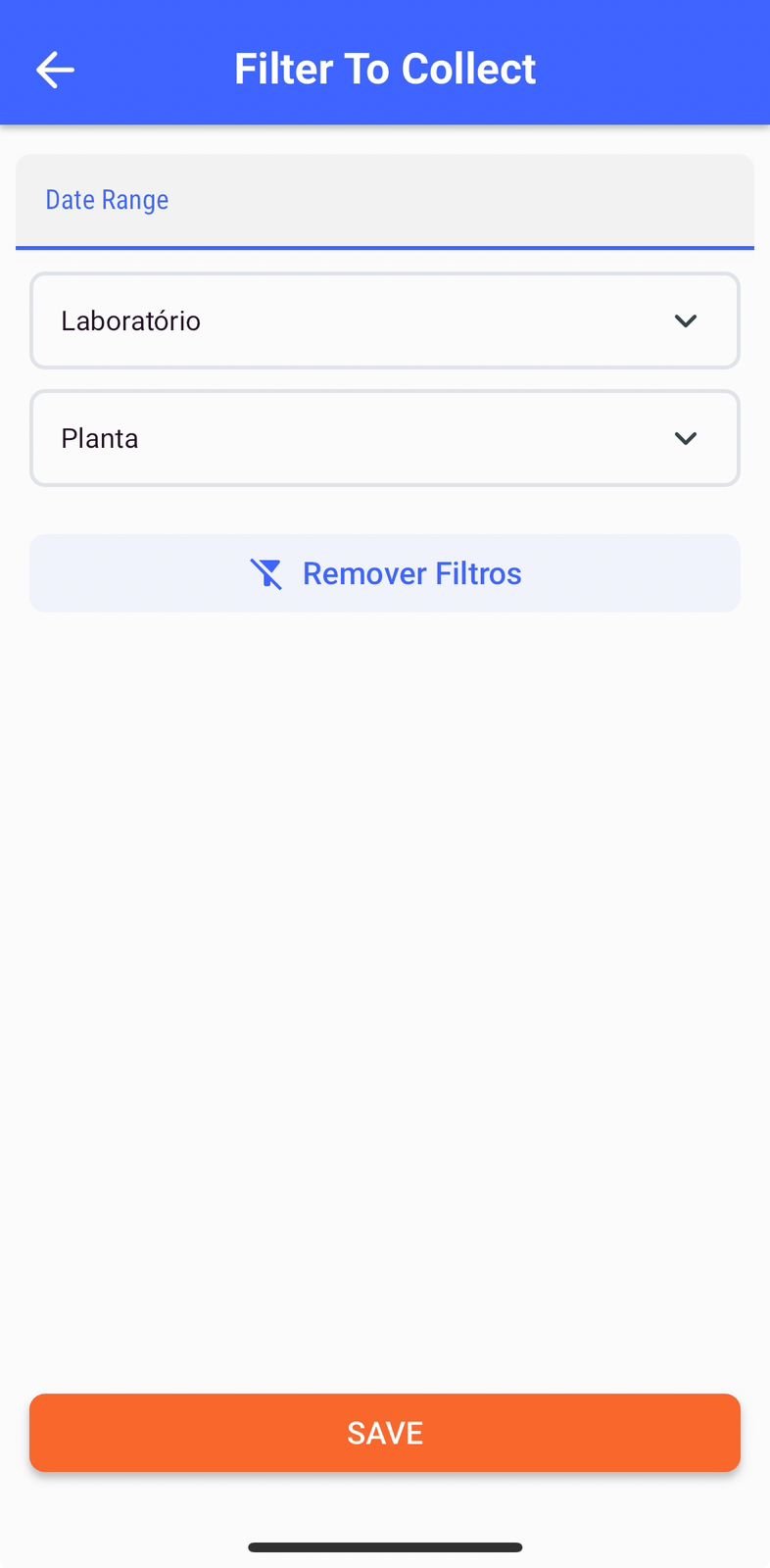

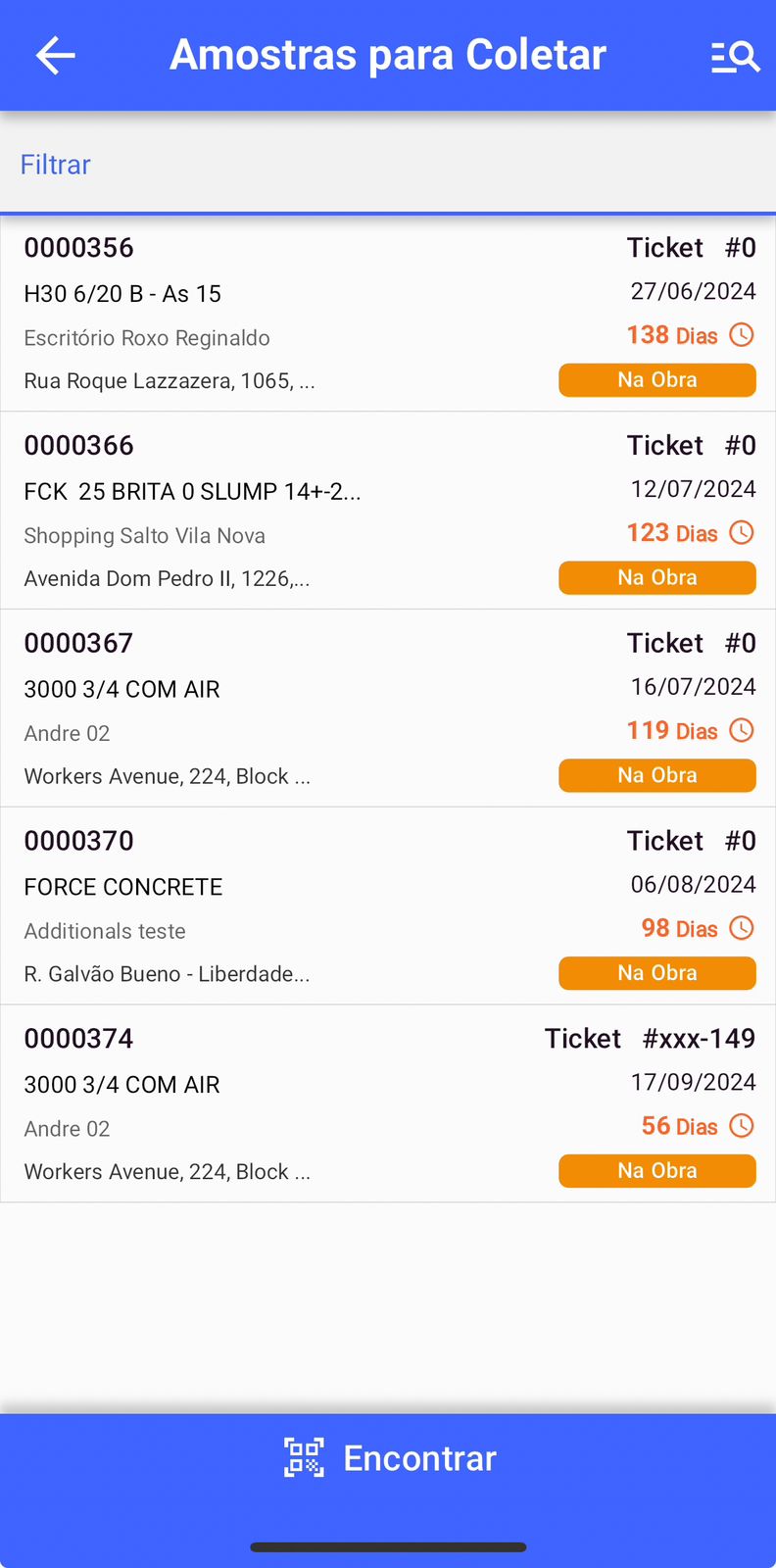

Filtering Samples to Collect

Using the filter, it is possible to locate inspections for a specific period, laboratory or plant.

The Collect section allows you to record the collection of concrete samples for quality control testing.

On this screen, you will see a list of all scheduled collections, including details such as:

Plant name

Sample code

Collection date

Days overdue

Collection status

Address

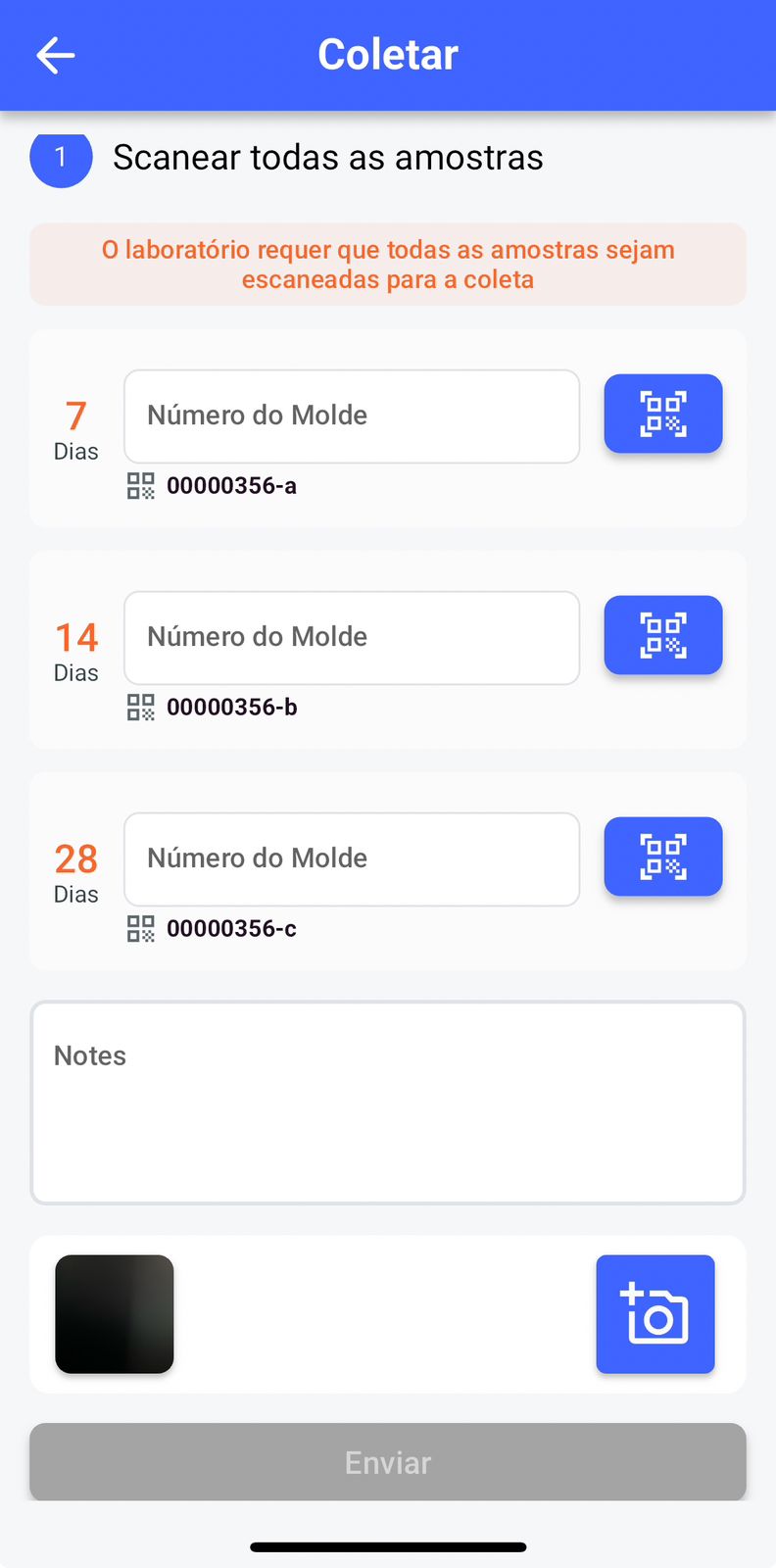

By selecting a collection, you can enter or scan the mold numbers, document in notes, and add images if necessary.

Receive

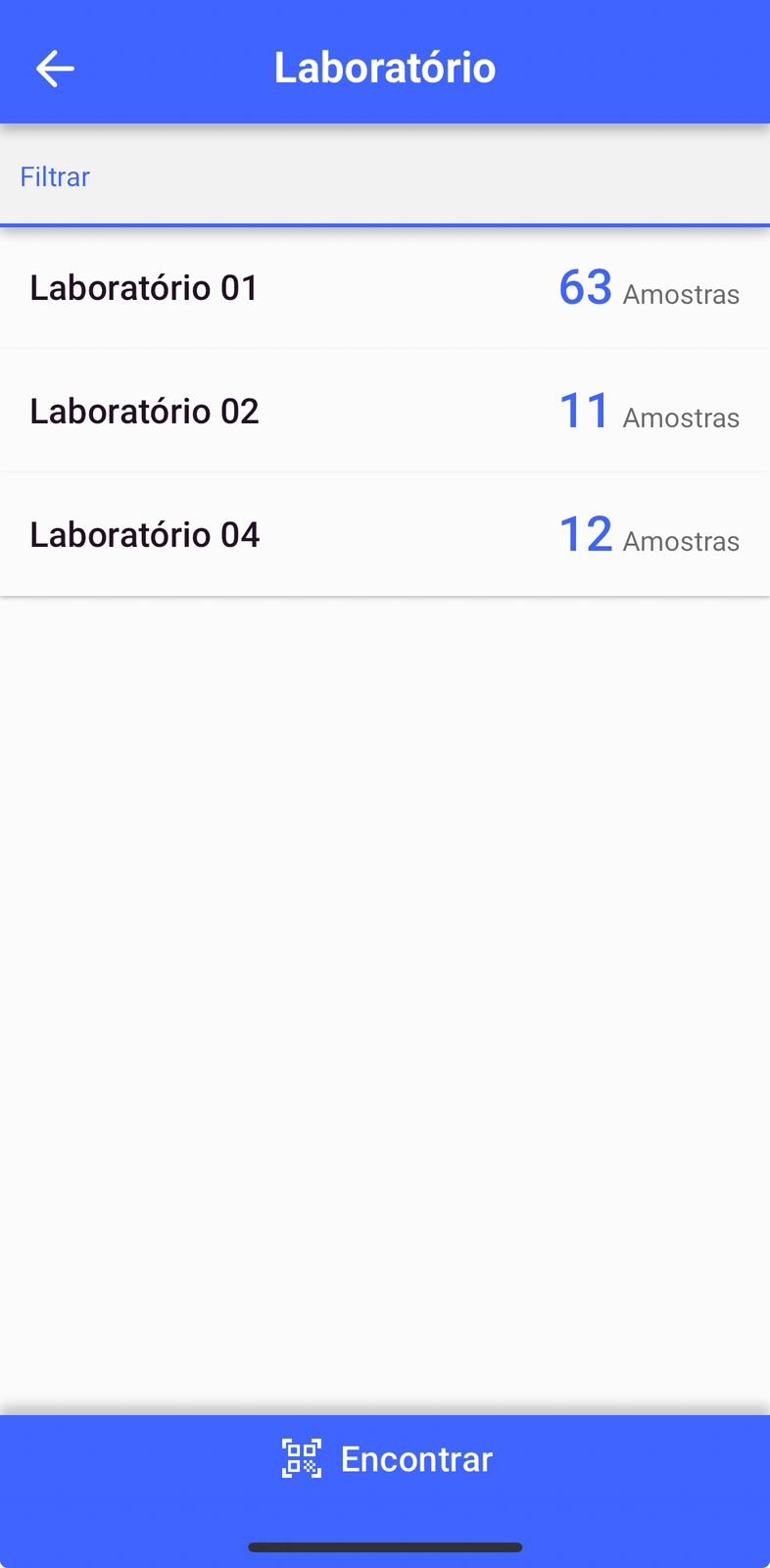

The Receive section in Loop QC is used to display samples to be received.

On this screen, you can see which user created the samples and the number of samples created by them.

By clicking on a sample to receive, you can select it and confirm receipt.

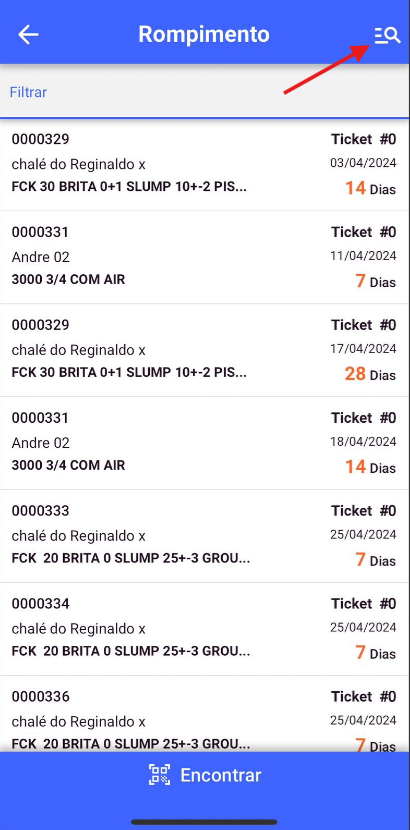

Break Up

The Break Up section in Loop QC is used to record the concrete sample break tests performed by the laboratory, verifying its strength according to established standards.

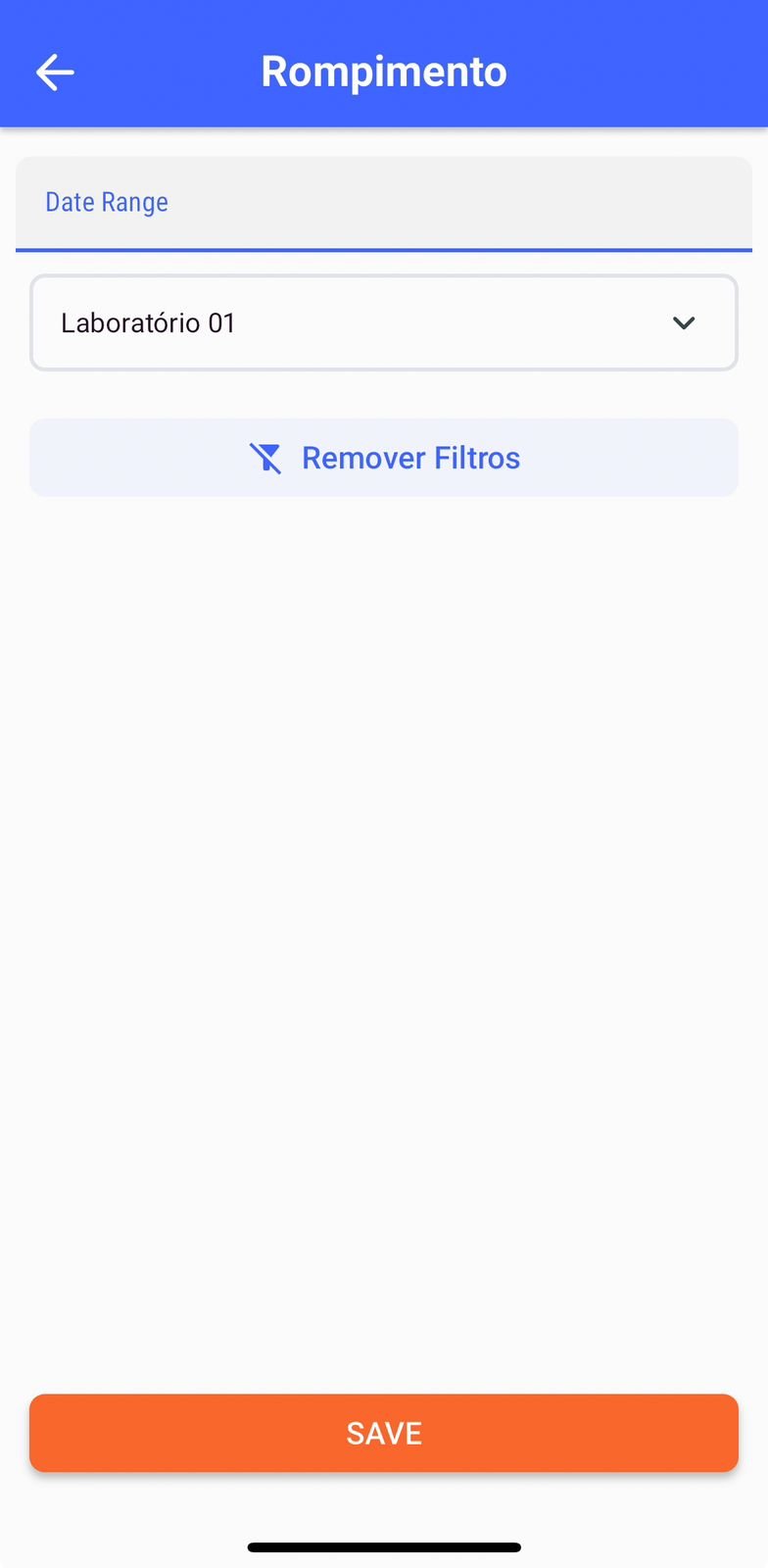

Filtering Samples to Break

Through the filter it is possible to locate inspections for a specific period and laboratory.

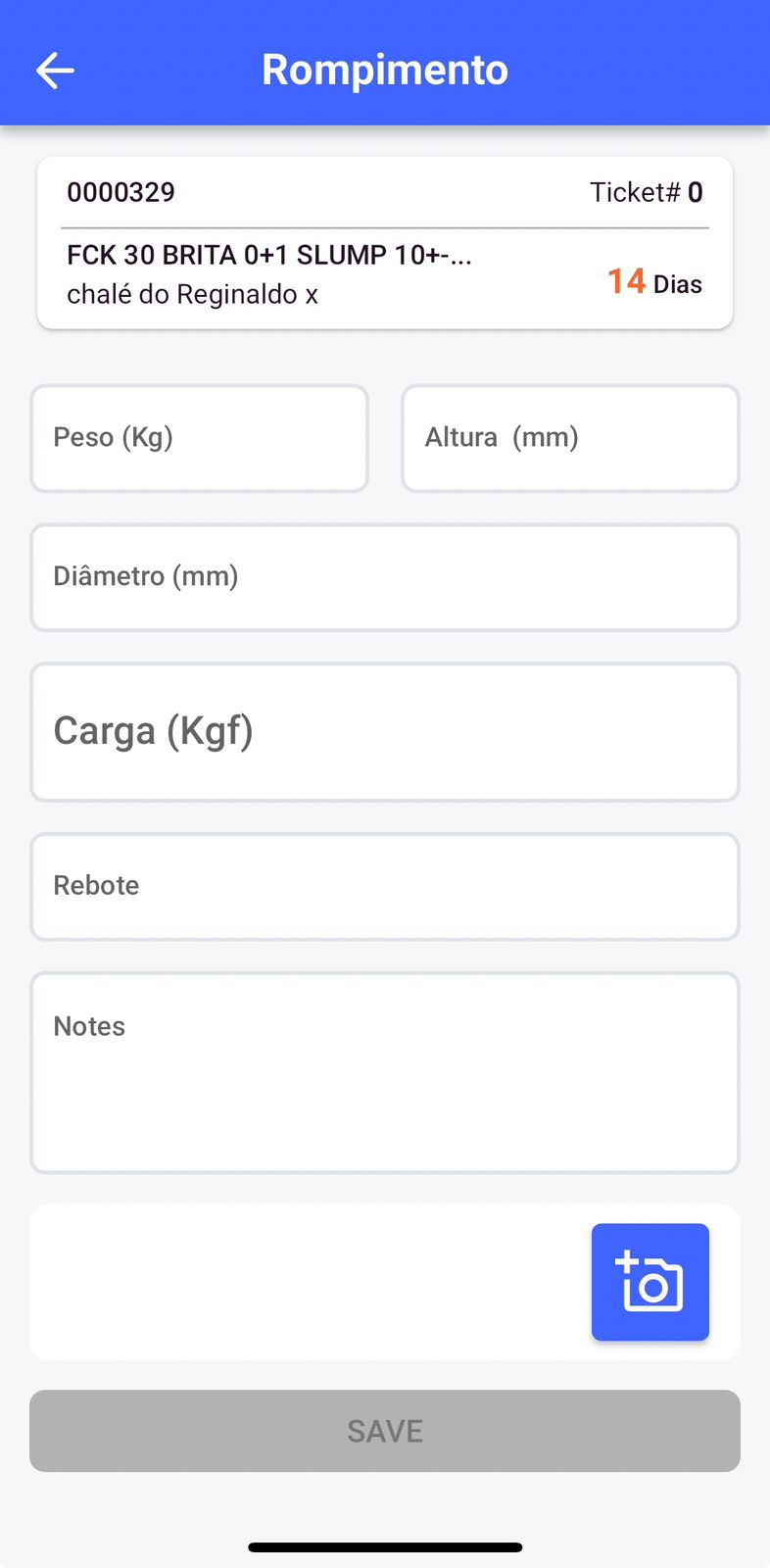

By selecting the laboratory, all samples pending tests will be listed, and you can locate them by QR Code. On this screen, you will see information such as:

Product name

Test code

Number of days

Test date

By selecting a sample, you will be directed to a screen where you must enter the concrete break information, including:

Weight

Height

Diameter

Load

Rebound

Notes (if necessary)

Image (if necessary)

Thank you for using our tutorial and we hope it was useful to you. We are always committed to providing the necessary information and assisting you in using our Loop 4 Readymix system.

Thank you for using our tutorial and we hope it was useful to you. We are always committed to providing the necessary information and assisting you in using our Loop 4 Readymix system.